In a meeting, during an audit or when filling in an evaluation grid, the question often comes up: what's the difference between a competence and a ability ? In practice, the two terms are used synonymously. And yet, confusing them can have direct consequences: a poorly positioned operator, a non-conformity during an audit, or even the suspension of production.

The distinction between competence and aptitude is not a semantic debate reserved for HR specialists. In an industrial environment, it shapes the way you assess, train and assign your teams. This article sets out the definitions, shows how these concepts relate to reality in the field, and provides keys to better manage them on a day-to-day basis.

What competence and aptitude really mean

In HR manuals, competence refers to an ability acquired through training and experience, while aptitude refers to a natural disposition. This theoretical framework, inherited from Guy Le Boterf's work on the triptych of knowledge, know-how and interpersonal skills, remains useful for understanding the fundamentals. But it reflects only part of the reality on the ground.

Herbert Zamora, who helps industrial groups manage their know-how, regularly observes this: during an invitation to tender in the aeronautics sector, the customer had named his project «aptitude project». Except that no one had exactly the same thing in mind. In the field, the hierarchy between these notions works differently from what we read in the manuals. And it's precisely this discrepancy that creates confusion.

Technical skills, the most granular level of know-how

In production, the technical competence corresponds to the most precise know-how, at the lowest level of granularity. It's an operator's ability to perform a specific task: work on a given machine, produce a product, apply a manufacturing process.

This skill is acquired through a structured training program. It develops with practice. But it also has a characteristic that many managers underestimate: it can be lost. In the aeronautics industry, for example, a technical skill has a limited service life (often 24 months after initial training). And a second counter runs in parallel: the non-mobilization period. If an operator is not assigned to a position requiring this skill for more than 180 days, it is considered lost.

In other words, a skill is not a definitive asset. It's a living skill that needs to be nurtured and sustained over time.

Aptitude, the umbrella term for skills and abilities

Contrary to what most articles on the subject say, aptitude in an industrial context is not simply a «natural disposition». It is a global authorization framework which determines whether an operator can intervene on a given workstation.

«It's a bit like Russian dolls. Ability is the last doll. Inside, you'll find technical skills and regulatory clearances.»

Herbert Zamora, Mercateam logo

Senior Account Executive Mercateam

Skills include :

- Visit technical skills required for the position (operational know-how)

- Visit regulatory approvals (external certifications, compliance)

- The validation all these elements are up to date and documented

Aptitude is therefore the last level of verification before authorizing an operator to produce. It guarantees, in the event of an audit or control, that each person on the job is qualified to be there. It confirms that the operator is versatile on the posts to which they are assigned.

Habilitation, a binary certification that bridges the gap

Between technical competence and aptitude lies a third element that is often confused with the other two: aptitude.’authorization. This is an external certification, issued by an organization or validated by a regulatory process. It is binary: you either have it or you don't.

Unlike technical competence, authorization has a simple, predictable lifespan (e.g. 12 months). It does not depend on frequency of use. Its renewal follows a fixed schedule. It's a stable benchmark in a system where skills are in constant flux.

The domino effect: why one lost skill can block an entire production line

This is the scenario that production managers dread: an operator loses a technical skill, often without anyone noticing in time. The corresponding skill is automatically suspended. The operator can no longer be assigned to the job. And if no qualified replacement is available, the production line grinds to a halt.

This cascading mechanism is particularly sensitive in regulated sectors. In aeronautics, standards EN9100 and customer audits require complete traceability of qualifications. Herbert Zamora cites a telling example: an air crash can trigger an investigation that goes back 15 years. The manufacturer then has to prove that the operator who tightened a given bolt, at a given torque, on a given part, was indeed qualified to do so at the precise moment of the operation, even if he left the company years ago.

The situations that trigger this domino effect are frequent. A long-term stoppage, a prolonged change of assignment, or simply a slack period on a line are all it takes to bring down a skill through non-mobilization. The problem, as Herbert Zamora points out, is that first-level managers are often «firemen on duty»: caught up in the urgency of day-to-day operations, they don't have the hindsight to anticipate validity deadlines. By the time the alert arrives, the skill has already been lost.

This is all the more true when management is based on Excel files or paper tables. The tools of skills management digital systems change the game by automating anticipation alerts. When a non-mobilization counter approaches the critical threshold, the system warns. When a clearance expires, renewal training is triggered in advance. The manager reacts before the suspension, not after.

How to acquire and assess a skill

Acquiring a skill cannot be decreed. It's a structured, multi-stage process, designed to ensure that the operator really masters the gesture. Herbert Zamora insists on this point: in the industrial groups he supports, we don't «give» a skill, we validate it through a rigorous qualifying process.

Visit qualifying course is generally divided into three phases:

- Content validation The operator views the operating procedures, quality sheets and instructions associated with the workstation. This step ensures that they have access to up-to-date information.

- Knowledge test A questionnaire or quiz is used to check that the information has been assimilated. This step is not systematic in all industries, but it is becoming more widespread.

- Tutoring and companionship An expert accompanies the operator in the field. In the aeronautics sector, validation may require the operator to complete 10 parts independently, under the supervision of the assessor, before the skill is officially acquired.

In addition to these three phases, we are increasingly adding a’self-assessment. Before the’in-plant skills assessment by peers or the manager, the operator himself assesses his level of mastery. This practice, which complements the external view, helps to identify areas of uncertainty and adjust the support provided.

The professional interview and the annual appraisal are the ideal moments to take stock of each employee's level, reassess acquired skills and plan future training.

An often underestimated point is the traceability of operating procedures. Procedures change regularly, sometimes several times a year. The manufacturer has to prove that each operator has seen the latest version of the document. A procedure has changed? If the operator hasn't read the update, the gesture he thought was the right one, or the machine settings he thought were correct, may no longer be. According to Herbert Zamora, tracing all this without a dedicated tool «is a real pain». And this is one of the points on which auditors, whether third-party audits (EN9100) or customer audits, most frequently penalize companies.

Structuring follow-up with a skills matrix

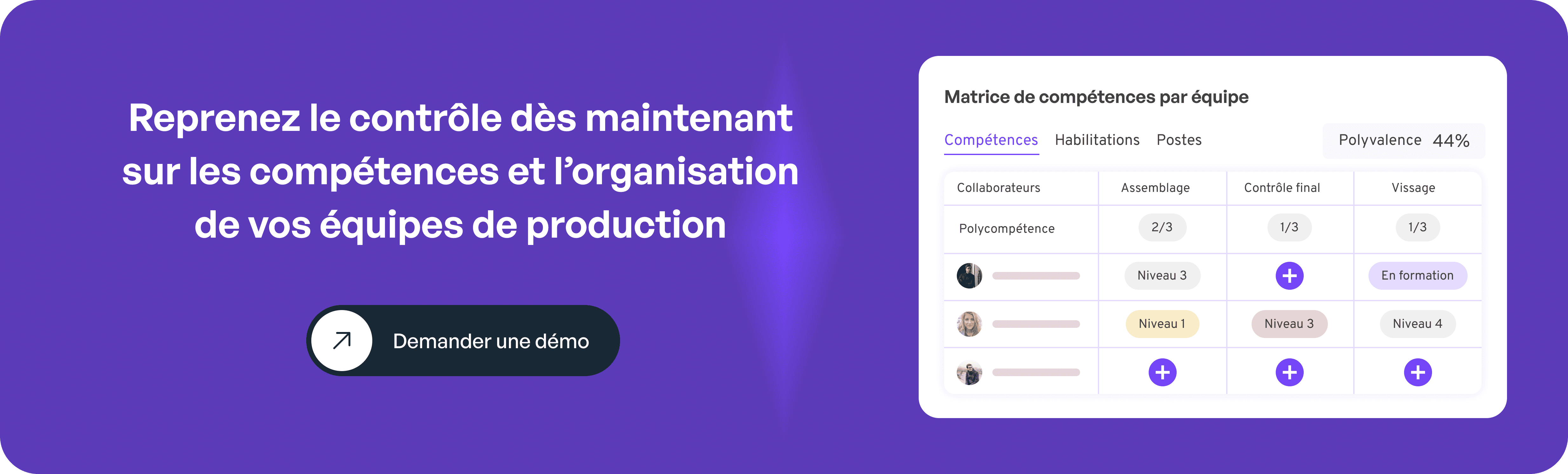

The skills matrix is the central tool for managing all these elements. It maps each operator's acquired technical skills, valid authorizations and active aptitudes.

To be truly useful, the matrix must integrate three dimensions: the level of expertise of each skill (novice, autonomous, expert), the due dates skills and competencies (to anticipate renewals) and the skills status (active, suspended, to be revalidated).

The main pitfall is updating. Herbert Zamora speaks of «insecure, fragile management» when tracking is based on Excel. A fixed matrix, updated once a quarter, no longer reflects reality after a few weeks. Skills expire, authorizations expire, assignments change. Without continuous updating, the matrix loses its reliability and becomes a false sense of security during audits.

That's why more and more industrial sites, such as Collins Aerospace, Bonduelle and Saint-Gobain, are switching to digital tools that centralize data in real time. The benefits are twofold: the manager saves time on administrative follow-up, and gains visibility on the real state of his team's skills.

The distinction between competence, empowerment and aptitude is not a theoretical subject. It's an operational lever that has a direct impact on the quality of your assignments, your audit compliance and the continuity of your production. By clarifying these notions, structuring their follow-up and anticipating deadlines, you give your managers the means to steer their teams with precision.

Mercateam supports more than 300 industrial sites in the management of their competencies, authorizations and skills. Request a demonstration to see how the platform can structure the monitoring of your teams.