Introduction

In the industrial sector, the schedule management is often perceived as an administrative burden rather than a strategic element. However, well thought-out planning can be the key determinant of the success or failure of an industrial enterprise. In this context, where time - a non-renewable resource - is vital, optimizing time management is crucial to improving productivity.

I. Why is scheduling essential in the industry?

The schedule management is not limited to organization. It is at the heart of industrial performance, and has a direct impact on many essential aspects of the business. From the point of view of productivity to that of the supply chain, effective planning is the cornerstone of successful operations.

Impact on productivity

Poor planning can have a negative impact on productivity.

| Problems | Consequences |

|---|---|

| Production delays | They can have a domino effect throughout the company. |

| Over- or under-utilization of resources | Without proper planning, you can end up with unused machines or premature wear due to overuse. |

| Decline in quality | Poor planning can put pressure on teams, which can affect the quality of the final product. |

| Cost increases | Delays and errors can lead to overtime and additional material costs, increasing production costs. |

Importance for the supply chain

Planning is not limited to production; it is intrinsically linked to the supply chain. Effective planning enables :

| Benefits | Explanations |

|---|---|

| Better coordination with suppliers | Precise planning enables you to communicate your needs to your suppliers in real time, improving coordination and reducing delays. |

| Optimizing stock levels | Good planning management helps you maintain optimal stock levels, avoiding the costs associated with overstocking or out-of-stock situations. |

| Improving customer satisfaction | Smooth, on-time production has a direct impact on customer satisfaction, which can be a major competitive advantage. |

| Agility in the face of the unexpected | Solid planning gives you the flexibility to react quickly to market changes or unforeseen events. |

II. 5 tips for optimizing your industrial planning management

Adopt a efficient planning software

In the digital age, it's essential to equip yourself with efficient digital tools to stay competitive. Planning software offers a multitude of advantages, including :

| Features | Benefits |

|---|---|

| Task automation | Scheduling software automates repetitive tasks, freeing up time for more strategic activities. |

| Real-time visualization | These tools offer interactive dashboards that let you track progress in real time. |

| Flexibility and adaptability | These solutions are often modular and can be tailored to your company's specific needs. |

| Integration with other systems | Most planning software can be integrated with other systems such as ERP or quality management systems. |

Set up relevant KPIs

Key performance indicators (KPIs) are essential for measuring the effectiveness of your planning management. Here are some KPIs to consider:

| KPI | Description |

|---|---|

| Resource utilization rate | Measures the percentage of resources used in relation to total capacity. |

| Production time | The number of hours or days required to complete a production cycle for a product or batch. |

| Synthetic rate of return (SRR) | An indicator that combines equipment availability, operational performance and product quality to assess overall efficiency. |

| Cost price | The total cost associated with producing a product, including direct costs such as materials and labor, as well as indirect costs such as equipment depreciation. |

| Versatility rate | Plant agility is becoming essential. Versatility multi-skilling is mandatory to ensure quality and safety. |

| Error-free assignment rate | The percentage of successful staff assignments, with the right person with the right skills assigned to the right job without errors or delays. |

| Number of skills allocated | The total number of distinct skills assigned to employees in the plant. |

| Number of authorizations granted | The total number of authorizations or certifications granted to employees to perform certain tasks or use certain equipment. |

| Rate of trained employees | The percentage of employees who have received adequate training to perform their respective tasks. |

Use Lean to eliminate waste

The Lean method is a proven approach to optimizing processes and eliminating waste. Here's how Lean can help:

| Benefits of Lean | Explanations |

|---|---|

| Identifying waste | Lean helps you identify the seven types of waste in your production process. |

| Continuous improvement (Kaizen) | Lean encourages a culture of continuous improvement in which every team member is involved. |

| Standardization | Lean standardizes best practices, making it easier to train and integrate new employees. |

Prioritize tasks with the Eisenhower matrix

The Eisenhower matrix is a simple but effective decision-making tool. It helps you classify tasks into four categories:

| Category | Action |

|---|---|

| Urgent and important | To be done immediately. |

| Important, but not urgent | To be planned. |

| Urgent, but not important | To delegate. |

| Neither urgent nor important | To be eliminated. |

Integrate planning into an overall strategy

Planning should not be an isolated activity, but integrated into the company's overall strategy. Here's why:

| Principle | Explanation |

|---|---|

| Alignment with corporate objectives | Effective planning must be aligned with the company's long-term objectives. |

| Taking external constraints into account | Planning must take into account external factors such as market fluctuations or regulatory changes. |

| Periodic review | The planning strategy needs to be reviewed and updated regularly to adapt to internal and external changes. |

III. How to choose the right industrial planning tool?

Selecting a schedule management tool Industrial automation is a strategic decision that can have a significant impact on your company's performance. With a multitude of solutions available on the market, how can you be sure you're making the right choice? In this section, we'll look at the essential selection criteria and briefly present Mercateamwhich stands out for its advanced features

Selection criteria

Before making a decision, it's crucial to consider several factors that can influence the tool's effectiveness. Here are a few criteria to consider:

| Features | The tool must offer functionalities such as resource planning, real-time tracking, and integration with other systems. |

| Cost | The cost should include the purchase price, as well as installation, training and maintenance costs. |

| Support and Customer Service | Good technical support and responsive customer service are essential. |

| Scalability | The tool must be able to adapt to your company's growth. |

| Data security | The tool must comply with current data security regulations. |

| Ergonomics and ease of use | An easy-to-use, intuitive tool will reduce training time and increase user adoption. |

The best solution: industry-specific shift planning software

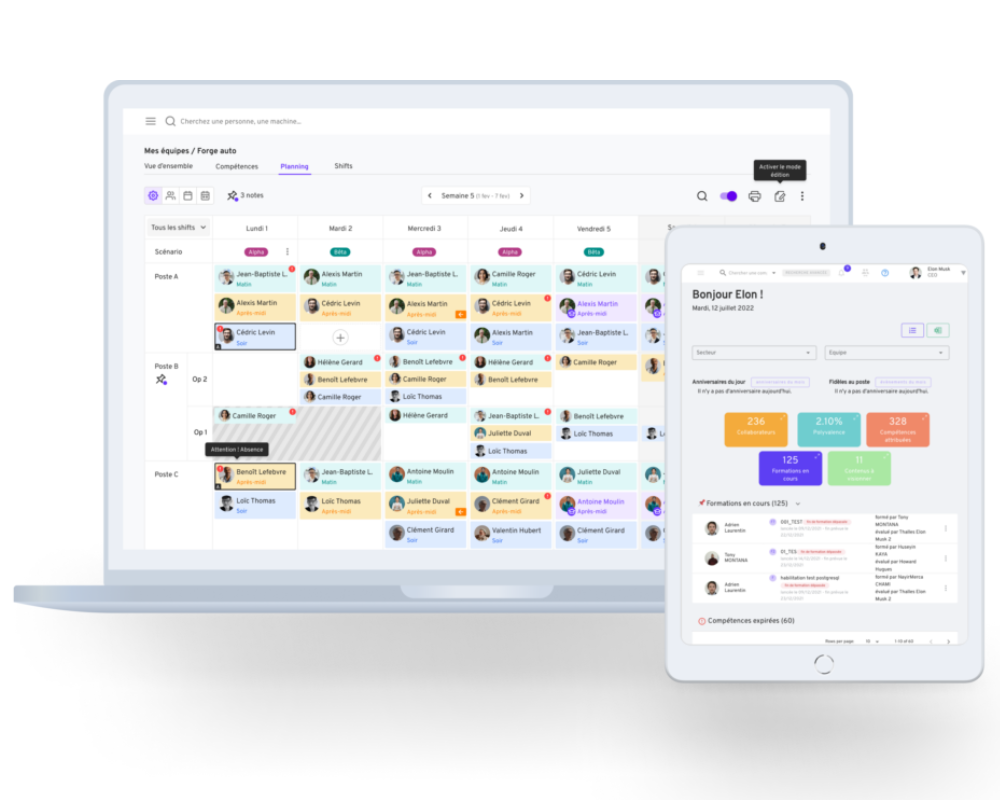

Mercateam Mercateam: Specializing in industrial know-how management, Mercateam offers a complete scheduling management solution. Its functionalities include skills management, planning, training, work instructions, and strategic workforce planning.

What sets Mercateam apart?

Mercateam offers a complete solution that goes beyond simple scheduling management. With features such as skills management and training, it enables a holistic approach to industrial know-how management. Adaptable, Mercateam was created with and for manufacturers, ensuring a hassle-free user experience.

In short, choosing the right scheduling tool depends on a number of factors, including functionality, cost and level of support. Mercateam stands out as a complete solution that can meet the most demanding industrial scheduling needs.

Conclusion

Industrial scheduling is not an easy task, but with the right strategies and tools, it can become a key success factor for your company. By taking a proactive approach and implementing the tips and tricks presented in this article, you can dramatically improve your planning management and increase your company's productivity and profitability.

Optimize your industrial planning now!