Introduction

In the world of the industrythe schedule management is far more than a simple work organization. It is a cornerstone that supports the entire edifice of the productivity and efficiency operational. Ignoring the importance of planningis to run the risk of seeing this edifice collapse under the weight of inefficiencies and unexpected costs. Let's take a closer look at the repercussions of a planning ineffective and the fundamental link between sound planning and productivity.

The crucial importance of schedule management in industry

- The repercussions of ineffective planning When planning fails, the effects are felt at every level of the company. From missed production deadlines to compromised customer commitments, the consequences extend far beyond the factory floor, undermining customer confidence and the company's brand image.

- The link between planning and productivity Effective planning is synonymous with optimum productivity. It ensures that resources are used strategically, minimizing downtime and maximizing output. Good planning is the conductor who harmonizes all industrial operations for a symphony of productivity.

I. The art of schedule management: more than a necessity, a strategy

Visit schedule management in an industrial environment transcends mere necessity; it is strategic. It represents a well-thought-out approach to orchestrating human resources and materialaimed at maximizing efficiency and minimize costs. Let's delve into the hidden costs of poor planning and the benefits of optimized management.

The hidden costs of poor planning

- Wasted time: a silent enemy Time is a precious and irretrievable resource. In industry, every hour lost through inadequate planning can translate into significant financial losses. From production delays to unexpected overtime, lost time is a hidden cost that weighs heavily on company finances.

- Impact on the production line: When every minute counts A production line interrupted or slowed down by poor planning is a money pit. Delays not only generate direct costs, but also affect product quality, customer satisfaction and, ultimately, the company's profitability.

The benefits of optimized planning

- Increased productivity: The secret of skilful management Efficient planning means optimum use of resources, less downtime and a significant increase in productivity. It's the art of doing more with less, while maintaining high production quality.

- Reducing operating costs: Saving through efficiency Good schedule management reduces costs associated with overtime, unscheduled machine maintenance and emergency management. By planning strategically, the company can make substantial savings, thereby increasing its profit margin.

In conclusion, the schedule management in industry is not just a question of logistics; it is a fundamental strategy for ensuring highest productivity and a efficient cost management. A optimized planning is the driving force behind a successful, competitive industrial enterprise.

II. The Road to Excellence: Optimizing schedule management

In the relentless quest for industrial excellencethe schedule management is a crucial lever. This section explores the integration of digital tools and best practices that are transforming the planning from a daunting task to a strategic opportunity to increase efficiency and flexibility.

Digital tools: the modern allies of planning

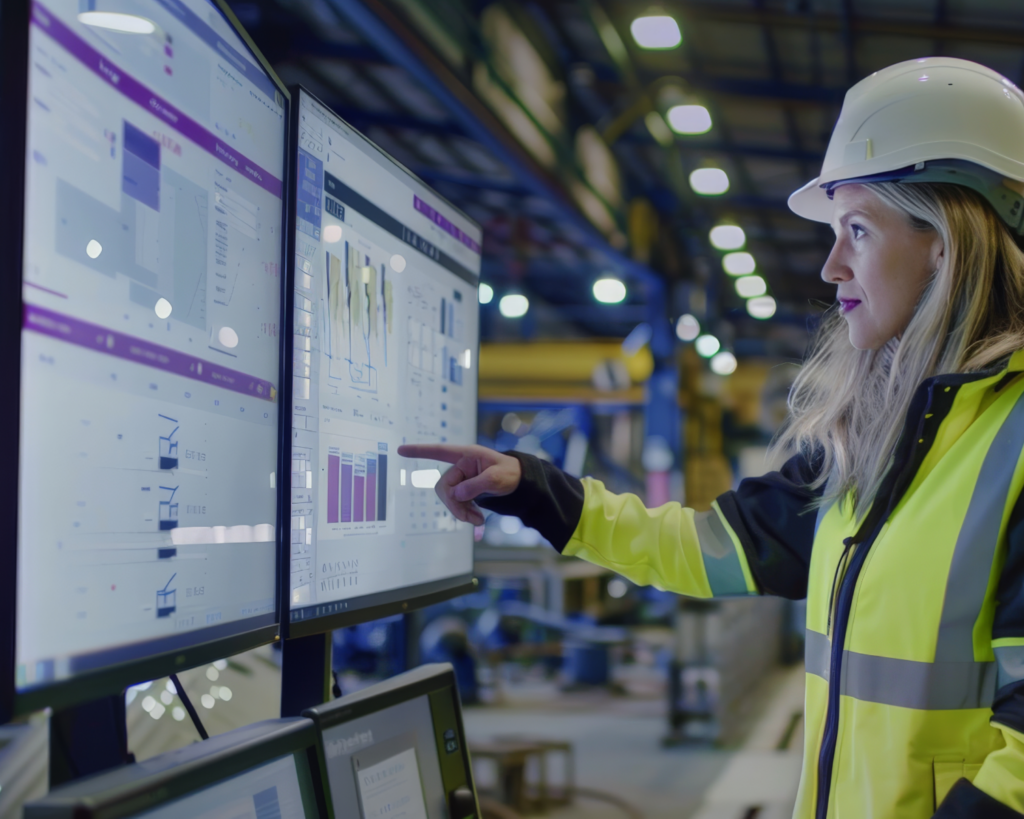

- Beyond Excel: The age of specialized software : The transition from Excel-based schedule management to specialized software marks a significant evolution. Not only do these tools offer greater ease of use and customization, but they also provide greater precision and accuracy than ever before. data integration unprecedented. From functionalities such as the real-time tracking, predictive analysis and integration of the different operational variables enable more dynamic and precise planning.

- Automation and AI: The quiet revolution : The integration of artificial intelligence and automation in the schedule management is silently transforming industry. These technologies make it possible to analyze massive amounts of data to optimize schedulesThey can also be used to forecast resource requirements and even anticipate potential problems. They free managers from repetitive tasks, allowing them to concentrate on strategic decisions. As demonstrated by Mercateam's automatic planning tool, which lets you add the most important tasks to your schedule with a single click. the right person, with the right skills, in the right job.

Best practices for effective planning

- Real-time planning: adapting to the unexpected In a constantly changing industrial environment, the ability to rapidly adapt schedules to unforeseen changes is essential. Real-time planning provides this flexibility, enabling companies to respond effectively to emergencies, supply chain delays or equipment breakdowns, minimizing disruption and associated costs.

- Flexibility and adaptability: the keys to a dynamic industry Modern industry demands unprecedented flexibility and adaptability in scheduling management. This implies the ability to rapidly reconfigure schedules, redeploy resources according to changing priorities, and maintain smooth production despite market fluctuations. What's more, training employees to multi-task and using versatile machines can greatly contribute to this flexibility, enabling companies to remain competitive and responsive.

By adopting these advanced digital tools and best practices industrial companies can take a significant step towards management schedules that doesn't just keep pace, but anticipates and adapts to tomorrow's challenges. Schedule optimization has become a driving force for innovation and competitiveness in modern industry.

III. Case studies: Turning theories into reality

To illustrate the concrete impact of a schedule management optimizedlet's explore two case studies where theory and strategy are translated into tangible results. These examples of Seb Group and LISI Aerospace demonstrate how adopting new approaches to planning can turn challenges into opportunities for growth and improvement.

Digital Transformation and Planning Optimization at Groupe Seb

The Challenge of Agility in a Changing Industrial Context : Groupe Seb, a global leader in the small domestic equipment sector, was faced with a strategic imperative: to increase its sales. agility and its versatility in the face of a constantly evolving industry. With a presence in almost 150 countries and a rich history of innovation, the group had to overcome the complexity of multi-site management, hampered by outdated, manual processes.

Concrete results: Time savings and improved efficiency : By teaming up with Mercateam, specialists in the digitization of industrial processes, Groupe Seb has succeeded in numerically transform and semi-automate schedule management. This collaboration has made it possible to standardize processes between different sites and optimize skills management, a crucial aspect for the group. The Mercateam tool introduced a common reference framework, enabling better anticipation of training needs and more effective skills management.

The result was a 30% reduction in time spent managing schedules and better allocation of human resources, contributing to a significant improvement in operating efficiency. The Group was also able to replace 35 Excel filesWord and PowerPoint with the Mercateam tool and digitized the entire 5 processesharmonization of skills tracking and the versatility on the Tournus and Rumilly sites.

Impacts and future prospects : Mercateam's digitization drive has resulted in a process harmonization within the Group, a significant reduction in the administrative burdenand better preparation for future training courses, with a total of 13 training courses launched. These advances were made possible thanks to a matrix of multi-skills digitized at 100%covering 569 skills assigned to 166 employees, and a Gestion Prévisionnelle des Emplois et des Compétences (Job and Skills Planning) (GPEC) optimized thanks to centralized and homogenized data. The success of Mercateam's rapid deployment, initially scheduled to take a month and a half, was also praised by Guillaume Hanoteau, the Group's Production Director.

Challenges in Competency Management at Lisi Aerospace:

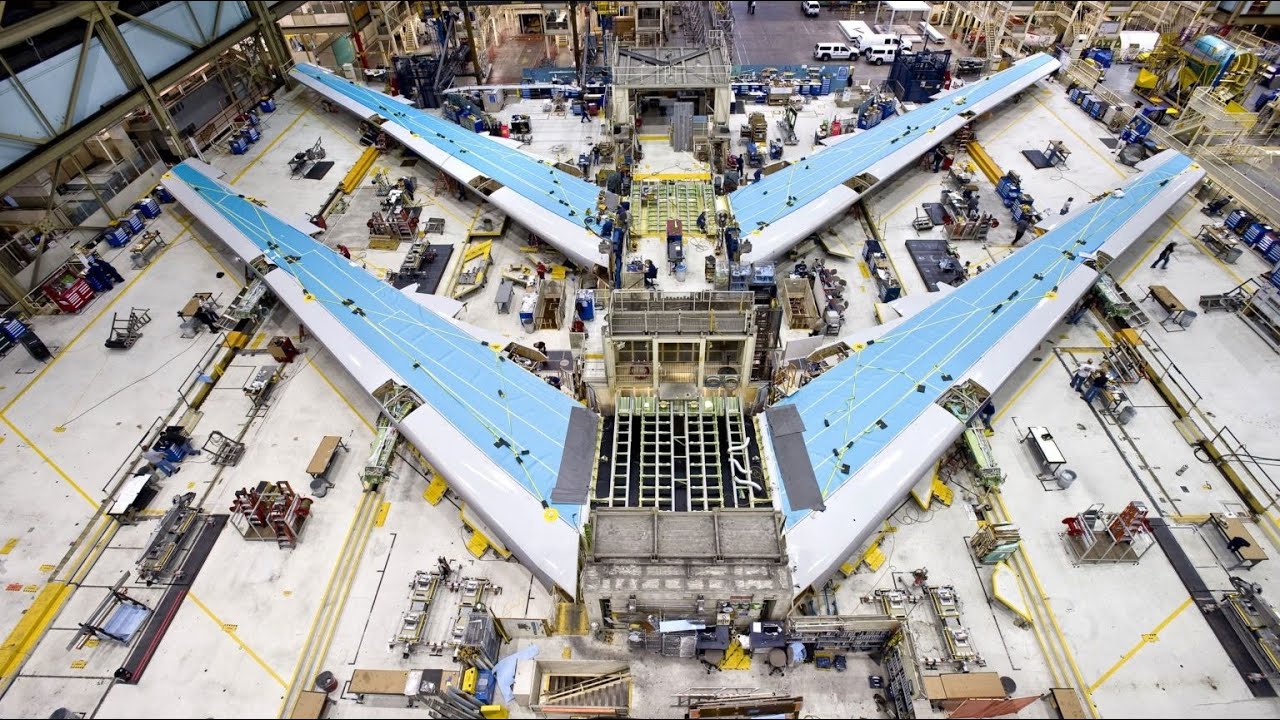

LISI Aerospace, a major player in the aerospace industry since 1977, operating in 9 countries and supplying essential components for all the world's aircraft, was facing challenges in the skills management and the planning. The need for a more flexible and dynamic solution was crucial to satisfying safety standards and quality standards.

Transformation towards greater responsiveness and agility The integration of the Mercateam tool marked a turning point for LISI Aerospace, which reinvented its operational management. Digitization has facilitated communication between the field and human resources, offering a new way of working. real-time tracking of skills and training. This development has enabled increase versatility within the 20% plant and double responsiveness and agility essential during the health crisis.

Notable advances and impacts of Mercateam deployment :

- Time savings and risk reduction Preparation for training audits has been considerably accelerated, and day-to-day management of absenteeism has been simplified, helping to reduce the health and safety risks associated with high-risk equipment.

- Improved Communication and Training Communication between support and the field has improved significantly, enabling Human Resources to plan training more efficiently and manage skills more effectively.

- Optimized planning Mercateam's digital planning system has facilitated rapid and precise assignments, taking into account absenteeism and employee skills, which has improved versatility and team involvement.

Concrete results and future prospects :

- Significant improvement in the working environment : The atmosphere in the field has improved considerably, reflecting a 20% increase in versatility within the plant.

- Doubled responsiveness and agility Our capacity to respond rapidly to challenges, particularly those posed by the health crisis, has been doubled.

- Reduced preparation and training time Audit preparation time was cut by a factor of three, and training time was reduced by a factor of four, thanks to a customized workflow.

These case studies show how leading companies in their fields have adopted innovative approaches for schedule management to overcome specific challenges. They demonstrate the importance of innovation in the planning to remain competitive and efficient in the ever-changing industrial landscape.

Conclusion

Summary and Reflection

- Schedule management: A pillar of industrial productivity : Our journey through the different facets of schedule management reveals that it's much more than simply organizing work schedules. time and resources. It's a crucial element that directly influences a company's productivity, efficiency and, ultimately, profitability. A planning is a powerful lever for driving industry success, by aligning human and material resources with business objectives.

Key points to remember

- Digitization, automation and real-time monitoring: the essentials.

If there's one lesson to be learned from our analysis, it's the vital importance of the digitalization and automation in modern scheduling management. The era of manual, reactive planning is over. Today, advanced digital tools, automation and real-time tracking systems are essential to remain competitive in a fast-paced, ever-changing industrial environment. These technologies are not just enablers; they are transformers that are redefining the way industry works, bringing unrivalled precision, efficiency and adaptability.