Every year, thousands of production hours are lost due to lengthy training courses, handling errors or unanticipated departures. An experienced operator retires, taking with him decades of know-how. A temporary worker arrives on Monday morning and has to be operational by the end of the week.

For some industrial jobs, it can take up to two years of training to build up skills. Two years during which productivity remains below target and the risk of error remains high. TWI can break down these long training courses into shorter, more targeted skill blocks, to speed up each stage of the skills enhancement process.

A team leader spends more time correcting errors than managing his line.

You're familiar with these situations. And they have a cost: in quality, in productivity, in turnover. Studies show that 20 % of new hires leave their posts within the first 45 days. Often because they have not been properly trained, supported or integrated.

The good news? A method has existed for over 80 years to solve these problems. It enabled the United States to increase production sevenfold in two years. It inspired the Toyota production system and the Kaizen culture. It's called Training within Industry, or TWI.

What is Training within Industry?

Training within Industry is an on-the-job training program developed in the USA in 1940. Its aim: to quickly and effectively impart field skills to unskilled or low-skilled workers.

At the time, the context was particular. President Roosevelt had just asked American industrialists to transform their factories to produce military equipment. The problem was that skilled workers were leaving for the front, and women, young people and people with no industrial experience had to be trained as a matter of urgency. Conventional training methods, long and theoretical, didn't work.

The War Department then created the TWI Service, which developed a radically different approach. Rather than teaching in classrooms, we train directly on the job. Rather than imparting general knowledge, the focus was on the precise gestures to be mastered. Rather than leaving supervisors to improvise, we give them a structured, reproducible method.

TWI thus laid the foundations for what would later be known as the on-the-job training, and is one of the historical foundations of Lean Manufacturing.

The history of TWI: from the war effort to Toyota

On May 30 1940, Roosevelt issued his appeal. Within a few months, 25,000 suppliers and 120,000 subcontractors were mobilized to produce what would become known as the «Arsenal of Democracy». Production increased threefold in the first year, and sevenfold in the second.

How was such a transformation possible? Thanks in large part to TWI. Between 1940 and 1945, the program 1.6 million workers in over 16,500 plants American companies. The results are documented: 86 % of participating companies improve their production, training time and productivity by at least 25 %. Some achieved gains of 500 %.

At the end of the war, the program came to an end in the United States. However, it enjoyed a second life in Japan. As part of the reconstruction process, TWI methods were introduced in 1951. Toyota adopted them and integrated them into its nascent production system. Job Instruction became the basis for standardized work. Job Methods inspire the culture of continuous improvement, the famous Kaizen. Job Relations lays the foundations for respect for people, a pillar of the Toyota Production System.

Today, companies such as Safran, Boeing, Volvo and 3M continue to use TWI to train their field teams. The method has survived the decades because it meets a permanent need: to pass on know-how reliably, quickly and measurably.

The three pillars of TWI

TWI is based on three complementary programs, often referred to as the «3 Js»: Job Instruction, Job Methods and Job Relations. Each addresses a specific need of field supervisors and managers. Some organizations add a fourth module, Job Safety, dedicated to risk prevention.

Job Instruction (JI): effective on-the-job training

Job Instruction is TWI's best-known module. It answers a simple question: how do you transmit a technical gesture so that the learner reproduces it correctly, safely and as quickly as possible?

The method is based on four steps:

- Prepare To get the learner in the right mood, explain what he's going to learn, check his prior knowledge and place him in a position where he can see and hear clearly.

- Present Demonstrate the operation, breaking down each step, then repeat it, highlighting key points and the reasons for them.

- Try Have the learner perform the operation, first in silence, then asking him to explain what he's doing and why.

- Follow Accompany learners in their first independent projects, answer their questions and validate their mastery.

The fundamental principle of Job Instruction can be summed up in one sentence: «If the learner has not learned, the instructor has not taught.» This approach gives the trainer a sense of responsibility and guarantees a real transfer of skills, not just a demonstration followed by a «you're on your own».

The benefits are immediate: reduced training time, fewer errors and rejects, improved workplace safety.

Digitized with a tool like Mercateam, Job Instruction becomes even more effective. The platform enables sequential instructions to be distributed within a training program in a variety of formats: video, photos, annotated diagrams. The pedagogical impact is far greater than that of a simple paper sheet. Employees can also independently validate their theoretical knowledge before moving on to practical exercises, which frees up the trainer's time and shortens the overall time needed to improve skills. Last but not least, Mercateam digitalizes the tutoring process: the trainer validates knowledge acquired directly in the field, with full traceability.

Job Methods (JM): improving work methods

Job Methods is aimed at supervisors who want to optimize the way work is done. The aim is not to revolutionize processes, but to achieve gains through successive small improvements.

The method starts by breaking down the work into elementary operations. For each operation, the supervisor asks a series of questions: Why does this step exist? Can it be eliminated? Can it be combined with another? Reorganize it? Simplify it?

This systematic questioning helps to identify waste, unnecessary movements, waiting times and superfluous handling. Ideas for improvement come from the field, from the people who carry out the work on a daily basis. This is exactly the principle that Toyota popularized under the name Kaizen.

A tool like Mercateam facilitates this dynamic: each employee can leave a comment directly on a training course to suggest an improvement, point out an obsolete step or share a tip from the field. Improving methods becomes a collaborative and continuous process, rooted in everyday life.

Job Methods is particularly effective when it comes to dealing with everyday irritants: a tool in the wrong place, a sequence of movements that could be simplified, a duplicate control. These small gains, taken together, produce significant results in terms of productivity and quality.

Job Relations (JR): managing human relations

The third pillar of TWI concerns the relationship between supervisor and team. Because training and improvement are not enough: we must also create the conditions for cooperation and commitment.

Job Relations is based on a simple principle: each person should be treated as an individual. This means getting to know your employees, recognizing their contributions, informing them of changes that affect them, and valuing their skills.

When a relationship problem arises, JR proposes a four-step method: gather the facts, analyze the situation, decide on an action, verify the results. The approach emphasizes the importance of relying on facts, not impressions or emotions.

In a context where staff turnover and absenteeism weigh heavily on industrial performance, Job Relations takes on its full meaning. An employee who feels respected, informed and valued stays longer and is more committed.

The benefits of TWI

TWI is not a theoretical method. Its results have been documented since the 1940s and continue to be measured today.

Historical data, collected from over 600 U.S. companies during World War II, show significant improvements:

- 86 % of companies improved their production, training time and productivity by at least 25 %

- Training time reduced to 90 % in some cases

- Scrap and rework decreased by 25 % or more for 55 % of participants

- Complaints and disputes fell by more than 30 % in 100 % of companies surveyed

Modern results confirm this effectiveness. Companies that rigorously apply TWI methods consistently report improvements in 50 % or more in targeted areas. Visit TWI Institute reports a 70 % reduction in workplace accidents at its customers. An electronics manufacturer reduced integration time by 30 %, assembly time by 20 % and absenteeism by 15 % thanks to a structured implementation.

These results can be explained by the very nature of the method: it standardizes what works, eliminates unnecessary variations, and gives managers the tools to train, improve and motivate their teams.

How to implement TWI in your plant

Deploying TWI does not require any radical transformation. The method has been designed to be accessible and progressive. Here are the key steps to successful implementation:

- Training supervisors in the TWI philosophy Supervisors, team leaders and local managers are the first to be affected. They need to understand the principles and master the techniques before applying them.

- Start with a module Job Instruction is often the starting point, as it meets the most immediate need (training new employees). But some organizations start with Job Methods or Job Relations, depending on their priorities.

- Field application with follow-up Each participant applies what he or she has learned to a real-life case. The classic format involves sessions lasting 2 hours a day over 5 consecutive days, with a return to the field between each session.

- Measure and adjust Documenting results (training time, errors, productivity) helps to demonstrate impact and identify any necessary adjustments.

- Gradually extend Once the first module has been mastered on a pilot workshop, roll it out to other teams and introduce subsequent modules.

Management sponsorship is a key success factor. TWI works when it becomes a daily practice, not a one-off project. The companies that achieve the best results are those that integrate TWI methods into their management routines and their training plan.

TWI and digitalization: moving from paper to modern tools

TWI was conceived at a time when everything was done on paper. Work breakdown sheets, training plans, skills validations: everything was handwritten, filed in binders, difficult to maintain and share.

This approach has its limits. When an operator changes jobs, how can we be sure that his new assignment corresponds to his validated skills? When a clearance expires, how can we know before the audit? When an expert retires, how can we capitalize on his know-how before it's too late?

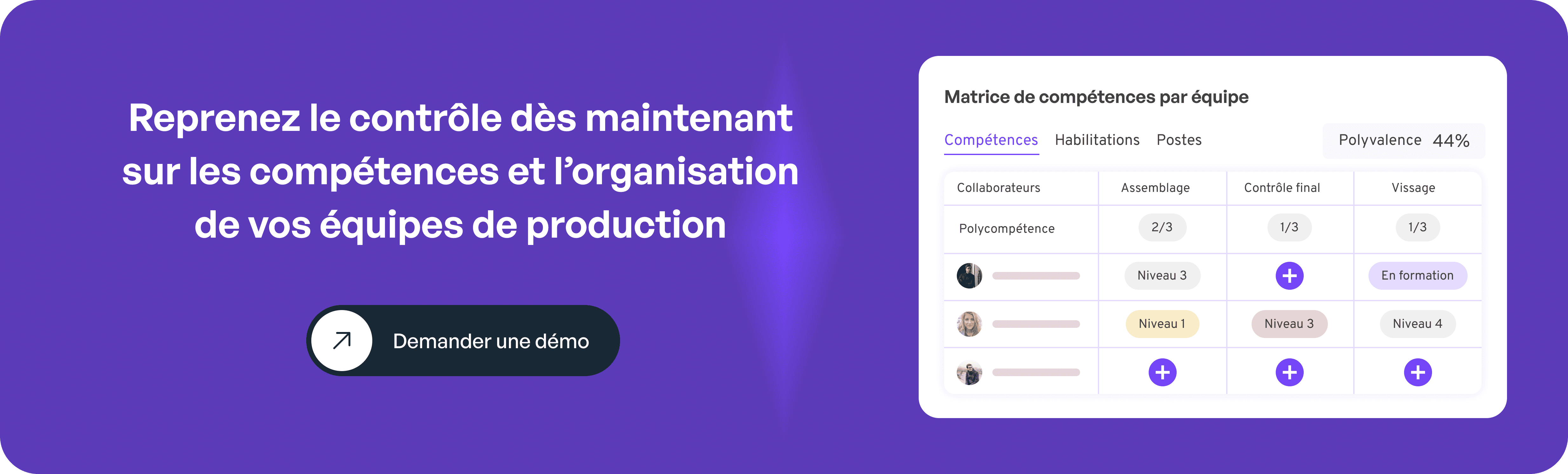

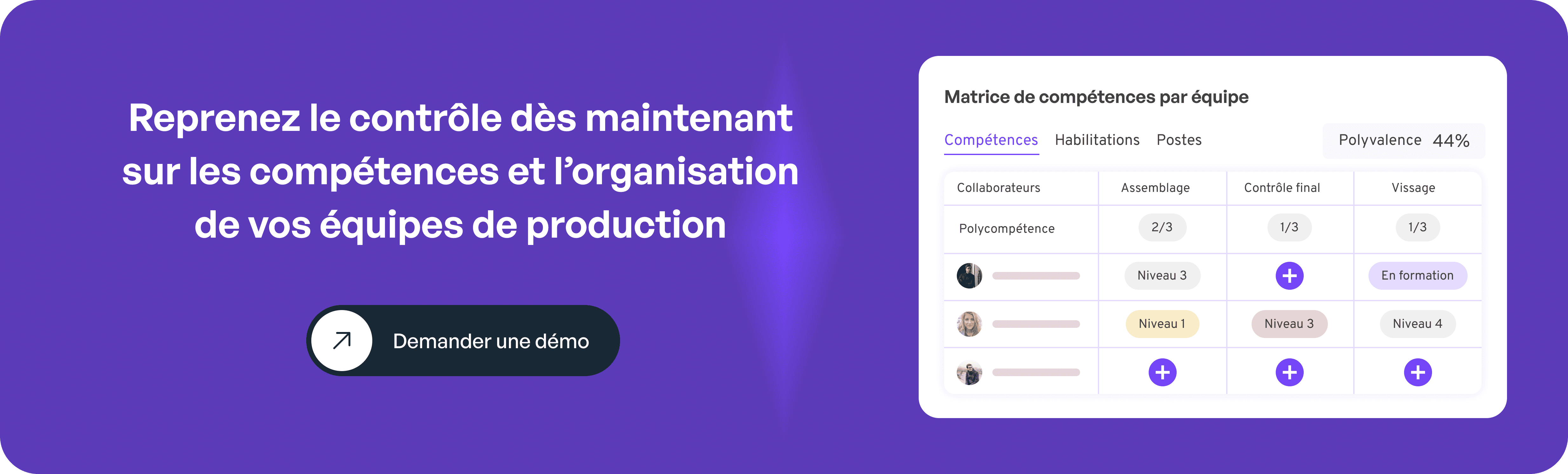

Digitalization makes it possible to meet these challenges without losing the essence of the TWI method. A skills matrix shows instantly who can do what, and identifies at-risk skills. Automated training paths guide the learner step by step, with validation by electronic signature. Alerts warn when a clearance is about to expire. Full traceability facilitates quality audits, whether to ISO, NADCAP or other industry standards.

This is exactly what a platform like Mercateam can do. Designed for industrial environments, it digitalizes skills management and on-the-job training. Mercateam also helps you define or challenge your skills repository to make it actionable in production and improve your productivity. The results are tangible: some customers have divided their training time by four. Collins Aerospace saves half a day a week on skills management. SEW Usocome has eliminated over 450 paper filing cabinets in favor of a centralized system accessible to all.

TWI remains the method. Digitization gives it the scale and durability that manufacturers need today.

TWI today

Training within Industry has spanned eight decades because it meets a universal need: to transmit know-how reliably, quickly and measurably. Its three pillars - Job Instruction, Job Methods and Job Relations - give managers the tools to train, improve and unite their teams.

Today, this method is even more powerful when supported by digital tools. Centralizing skills, automating training paths, securing traceability: it's the combination of TWI and technology that enables manufacturers to meet today's challenges.

Would you like to find out how to digitalize training and skills management at your plant? Request a Mercateam demo.