Neotiss faces organizational challenges

Before implementing Mercateam, Neotiss faced several challenges in managing its operations at its Venarey-les-Laumes site:

- Lack of follow-up on information dissemination : Employees had to consult numerous documents to work, but keeping track of their distribution, especially after updates, was complex.

- Lack of real-time monitoring of skills and authorizations Skills management was carried out in Excel or in an informal way, making information difficult to access and not shared between teams.

- Inefficient schedules : Schedules were drawn up in Excel, printed out and posted, which meant a heavy reliance on the "head" knowledge of the production manager and time-consuming tasks with little added value.

These problems were holding back productivity and jeopardizing the transmission and maintenance of industrial know-how.

Why Neotiss chose Mercateam to digitalize its industrial know-how

To meet these challenges, Neotiss chose Mercateam to :

- Optimize management of skills and authorizations Digitize and centralize this information to anticipate the loss of know-how, with the aim of :

- Remove 100% from Excel & paper files related to skills management, authorizations and training follow-up;

- Digitizing 100% on-site skills and authorizations ;

- Digitizing 100% of CTSE and Modes opératoires ;

- Semi-automated scheduling of on-site employees

- Standardize and modernize processes To make the distribution and management of training content simpler and more efficient.

- Reduce the administrative burden Automate schedules and centralize data to free up production teams' time.

Mercateam has made a name for itself thanks to its ability to structure data, digitize documents and support teams in adopting new tools.

How Mercateam helps Neotiss optimize its process management

During the Mercateam rollout, several initiatives were undertaken:

Complete digitization of processes

- Eliminate all Excel files and paper documents linked to skills management, authorizations and training follow-up.

- Digitization of 100% technical documents (CTSE and operating procedures) for structured, simplified access.

Semi-automated planning

- Creation of a global schedule shared and used by 100% team leaderswith real-time skills tracking.

- Reduces the time needed to create and update schedules, improving internal coordination.

Training and structuring

- Mercateam training for production teams, supervisors and HR staff.

- Integration of 800 documents digitized in less than 3 weeks.

Anticipating risks

- Centralization and reporting of KPIs on skills and authorizations for a clear, unified vision.

- Automatic notification of expiry of skills and authorizations with 3 months in advance.

In less than three weeks, Neotiss digitized over 800 documents, considerably simplifying document management. The adoption of a semi-automated global schedule by all teams reduced time-consuming administrative tasks, while automated notifications reinforced risk anticipation by flagging expiring authorizations three months in advance.

Mercateam has enabled Neotiss to modernize its operations while preserving its industrial know-how and significantly improving productivity.

About Neotiss

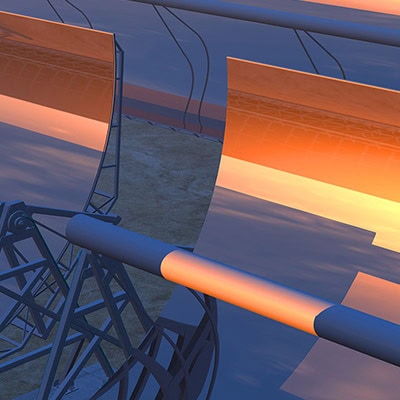

Neotiss is an international group present in 4 countries: France, USA, China and India. In France, the Venarey-les-Laumes site has been manufacturing high-quality pipes for various sectors (nuclear, domestic, etc.) since 1976. Historically established in the nuclear sector, Neotiss offers top-quality pipes to meet the most demanding requirements and constraints.