Introduction

Visit production planning is an organizational tool that defines the scheduling of all activities required for manufacturing. It enables you to methodically organize your operations according to customer orders, production capacities, available manpower and deadlines.

For industrial companies, efficient production planning represents an undeniable competitive advantage. More than simply organizing work, it is a strategic lever for optimizing resources, guaranteeing product quality and meeting customer commitments.

1. The challenges of production planning

Meet delivery deadlines

A production planning you can honor your commitments to your customers. By methodically organizing production steps according to orders and production quantities, you ensure on-time delivery.

Delays can have major consequences: financial penalties, deterioration in customer relations, even loss of business.

Optimizing the use of resources

Precise production planning means that all available resources - machines, personnel, raw materials and storage space - can be used to best effect.

A well thought-out schedule reduces equipment downtime and avoids unnecessary mobilization of personnel, enabling these resources to be reallocated to higher value-added tasks.

Improving productivity

The methodical organization of production activities naturally leads to a improved productivity. By anticipating resource requirements and intelligently sequencing operations, you can reduce waiting times between production stages.

Reduce production costs

Efficient production planning makes a significant contribution to cost reduction. By anticipating raw material requirements and optimizing procurement, you can avoid costly emergency purchases.

Reduced machine downtime and better use of human resources also mean lower operating costs.

2. The essential components of a production schedule

Customer orders

The basis of all production planning is customer orders. This sales data is the starting point for determining production quantities and production sequencing.

Effective planning incorporates not only firm orders, but also sales forecasts, enabling us to anticipate future needs.

Machine production capacity

Precise knowledge of your equipment's capacity is essential for realistic planning. This includes machine output, availability (including scheduled maintenance), changeover times and production rates for each part number.

Availability of manpower

The human factor remains central to any industrial process. Your planning must therefore take into account vacation schedules, planned training, anticipated absences and the skills of each operator.

Raw materials inventories

Before launching production orders, it is imperative to check the availability of the necessary components. A schedule disconnected from actual stocks could lead to supply shortages and costly production stoppages.

Integrating stock data into your planning enables you to anticipate supply needs and avoid shortages.

Manufacturing lead times

Each product has its own manufacturing cycle, with specific times for each stage. Accurately factoring these times into your planning is essential to establishing realistic delivery dates.

3. From planning to execution: key stages

Planning and scheduling

Planning and scheduling are two complementary but distinct processes. Planning takes a medium- to long-term view, analyzing production capacity in relation to forecast load. Scheduling, on the other hand, focuses on the short term, determining precisely which production order needs to be processed when.

These two steps are fundamental to efficient production planning. Planning enables us to anticipate resource requirements, while scheduling optimizes the sequence of operations to maximize productivity while meeting deadlines.

Resource allocation

Once the overall plan has been drawn up, the precise allocation of resources involves assigning the machines, operators and raw materials required for each production task.

This stage requires detailed knowledge of the capabilities of each resource. Knowing that an operator masters certain machines perfectly, or that a specific piece of equipment is particularly well-suited to a particular reference, enables us to optimize allocations. Efficient planning takes into account the skills of each individual to place the right person in the right job.

Prioritizing tasks

Faced with multiple orders with varying deadlines, prioritization becomes a strategic step. It involves determining the order in which production tasks will be carried out, according to their importance, customer deadlines and technical constraints.

A well thought-out prioritization system helps to avoid bottlenecks and streamline production. It takes into account not only the urgency of orders, but also changeover times, resource availability and interdependencies between different tasks.

Managing the unexpected

Even the best-designed schedule has to adapt to the vagaries of production: machine breakdowns, unexpected absences, late deliveries from suppliers or urgent orders.

The ability to react quickly to these unforeseen events often determines the real effectiveness of a planning system. Good planning doesn't just follow a pre-established plan, it offers the flexibility needed to adapt to changes while minimizing their impact on overall production.

4. The benefits of digital production planning

Save time and reduce errors

Digitizing production planning automates time-consuming, repetitive tasks, freeing up time for higher value-added activities. It also reduces the risk of errors inherent in manual processes.

Better visibility and responsiveness

Digitized production planning provides an overview of industrial activity, accessible to all those involved. This transparency facilitates coordination between departments, and enables faster, more relevant decision-making.

Real-time data for informed decisions

Digitization makes it possible to collect and analyze production data in real time. This valuable information helps managers to make decisions based on facts rather than intuition.

Analysis of historical data also enables us to identify trends and anticipate future needs.

5. How Mercateam transforms your assignment planning

Solution overview

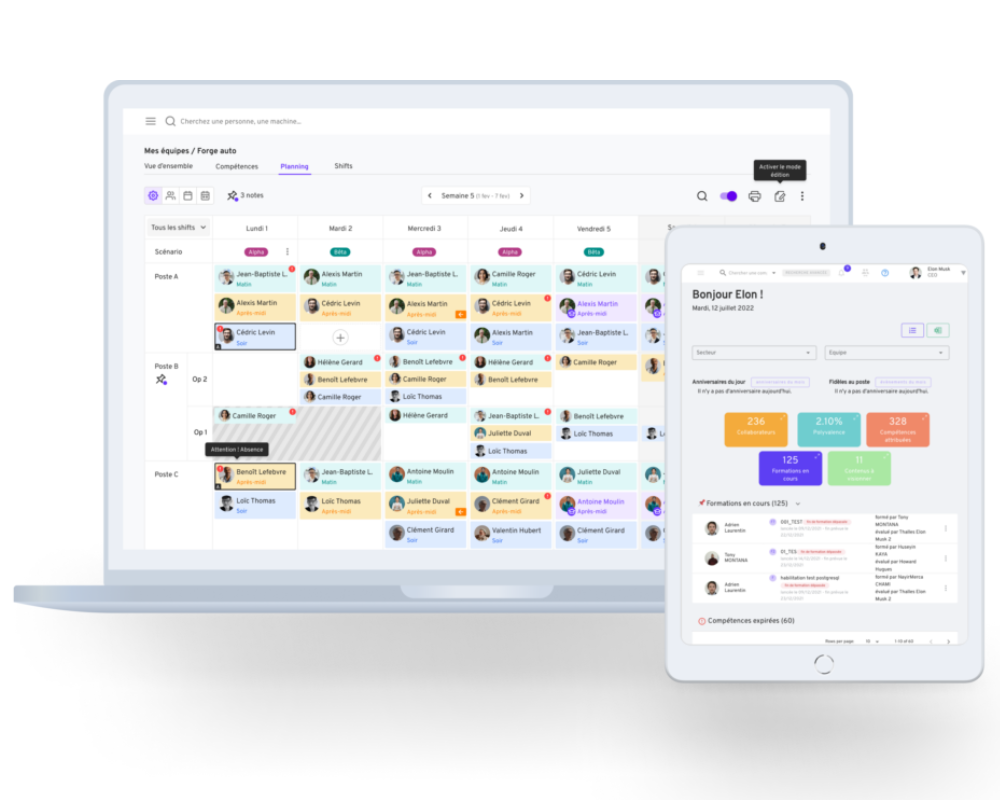

Mercateam offers a complete scheduling solutiondesigned specifically for industrial environments. Our platform makes it possible to efficiently manage the assignment of operators to workstations, taking into account their skills, availability and production requirements.

Our approach puts people at the heart of the system, considering that employee development is a key factor in industrial performance. The solution adapts to your existing processes to provide an intuitive user experience for managers and operators alike.

Special features

Mercateam stands out for its innovative features:

- A automatic assignment system instantly suggests the most suitable operators for each position, based on their skills and availability

- Dynamic skills management to monitor team versatility and anticipate training needs

- Alerts in the event of expired authorizations or risk of loss of critical skills

- Real-time monitoring of actual assignments compared with forecast schedules

The platform also offers customizable dashboards that provide a clear view of key performance indicators linked to human resources management in production.

Integration with your existing systems

Mercateam integrates easily with your tools such as ERP, time management software (ADP, Workday, OroQuartz), or MES systems. This interoperability enables data synchronization and avoids double data entry.

The solution adapts to your organization and processes, enabling rapid implementation and easy adoption by your teams. Several integration methods are available: via API, automated file transfer or SFTP, depending on your technical constraints.

Concrete results for our customers

The results obtained by our customers testify to the effectiveness of our solution:

- At SEBWith Mercateam, we saved 30% of time managing schedules per week, with 35 Excel files replaced by Mercateam.

- At Sagemcom, 100% of skills and authorizations have been digitized, enabling 101 employees to be better valued.

- LVMH Fragrance Brands has been able to minimize assignment errors thanks to the constraints set when the tool was set up and the visual alerts that immediately identify anomalies.

These results demonstrate the tangible impact of our solution on industrial performance and team satisfaction.

Conclusion

A well-executed production schedule is a major performance driver for industrial companies. It enables them to meet delivery deadlines, optimize resource utilization, improve productivity and reduce production costs.

Mercateam supports you in this process with a solution tailored to your specific challenges, which puts people at the heart of the process. Our pragmatic approach and in-depth knowledge of industrial environments enable us to offer you a tool that precisely meets your needs.