Industry 5.0 is about to usher in a new era, marked by significant improvements in terms of the work we do and the technologies we use. While we're still immersed in the fourth industrial revolution, the future of industry is slowly but surely taking shape.

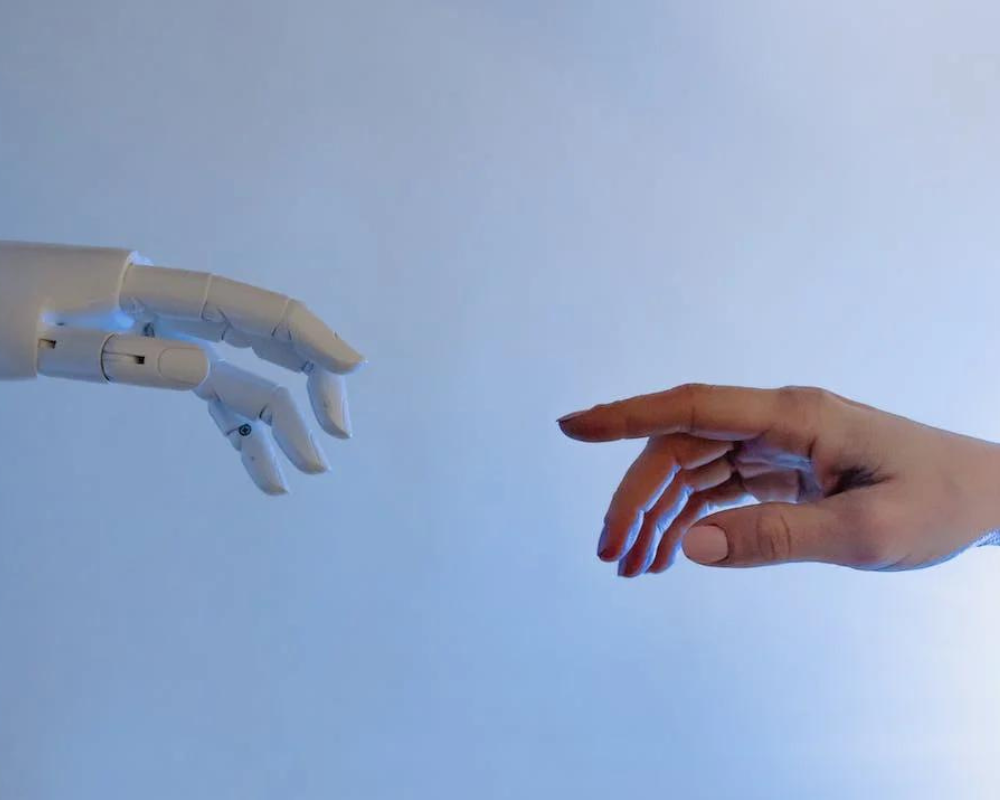

We're already talking about Industry 5.0, which brings a new way of thinking about the relationship between intelligent machines and humans.

In this article, we take a look back at the major periods that have shaped the industry, as well as a glimpse of what lies ahead in Industry 5.0.

Industry 1.0 - The age of steam and coal

Dating back to the 1760s, the first Industrial Revolution marked an important turning point in history. It marked the transition from classical craftsmanship to new manufacturing processes. New fuel sources such as steam and coal accelerated the adoption of machines.

This upheaval made it possible to produce goods in greater quantities, notably in the textile industry, where machines generated a yield up to eight times greater than what could be obtained by hand. The first industrial revolution was also synonymous with new modes of transport, such as the boat and steam locomotive.

Industrie 2.0 - The historic upheaval

It was in the 19th century that major discoveries overturned existing manufacturing processes. Electricity, gas and oil were the new energy sources powering production plants.

The second industrial revolution led to the creation of the combustion engine. It also led to the development of the steel trade, chemical synthesis and means of communication such as the telegraph and telephone.

Finally, the inventions ofautomotive and theaircraft in the early 20th century are the reason why, to this day, the second industrial revolution is considered the most important.

Industrie 3.0 - The IT revolution

Around 1970, the third industrial revolution involved the use of electronics and computers (information technology), making it possible toautomate part of the production lines. Some programmable robots are now capable of performing all kinds of tasks, without the need for human intervention. As a result, manufacturing methods are advancing considerably, and this is accelerated by Internet access within factories.

This period is also marked by the use of renewable energies. Indeed, part of the third industrial revolution is based on energy transition, moving away from coal and towards cleaner energy sources.

Industrie 4.0 - Today's world

The fourth industrial revolution is the era of intelligent production machines, capable ofexchange informationand control itself autonomously without human intervention.

This exchange of information is made possible by the Industrial Internet of Things (IIoT) as we know it today. Industry 4.0 is characterized in particular by:

- The use of cyberphysical systemsThese are computer algorithms used to control a fleet of machines.

- The Internet of Things (IoT): interconnected networks of machines and vehicles equipped with computerized detection, digitization and surveillance capabilities.

- Visit Cloud computingIn other words, the hosting and backup of data away from the production site.

- LCognitive computing - technology platforms using artificial intelligence.

Industrie 5.0 - The industry of tomorrow

Barely 10 years after the term "Industry 4.0" first appeared, Industry 5.0 is already on the horizon, defining the challenges that tomorrow's factories will have to meet thanks to the progress it brings.

If Industry 4.0 focuses on the transition to intelligent factories, driven by data exchange, Industry 5.0, meanwhile, should refocus attention on people.

So how does Industry 5.0 differ from the factory floor as we know it today?

First, industry 5.0 promotes a more ethical visionIn this way, the company's strategy will be based on a holistic approach, integrating factors such as sustainability, the environment and social aspects. In Industry 5.0, rather than basing corporate strategy on the logic of production performance, the focus is on the following factors the people who will be the cornerstone of the plant's competitiveness.

Next, industry 5.0 envisions tomorrow's plants equipped with the latest technologies. designed to go further in improving working conditions, such as mental and physical fatigue detectors at the workstation.

Finally, in the context of Industry 5.0, taking the environment into account is becoming a key issue. We can envisage new ways of recycling waste, using renewable energies or integrating sensors to reduce energy consumption.

Thus, Industry 5.0 can be characterized by :

- The desire to support, not replace humans

- Striking a balance between productivity and efficiency

- An approach that minimizes environmental impact

In a nutshell

With the acceleration of technological innovation, revolutions at the heart of industry could follow one another in rapid succession over the next 10 years and beyond. Whereas the first three industrial revolutions took decades to materialize, today's revolutions last only as long as it takes for them to be adopted by a majority.

The development of Industry 5.0 is more an upgrade of Industry 4.0 than a revolution in its own right. As artificial intelligence improves and robots become increasingly autonomous, the interaction between computers, robots and humans should become clearer, leading to a revival and improved attractiveness for industrial professions.